Engine Driven Water Desalination Systems

These water makers are the perfect seawater to drinking water machines. At Cruise RO Water and Power, we provide the best-quality water desalination systems. We offer reasonable price and with warranty included.

Benefits of an Engine Driven Water Desalination Systems

- Energy Efficient: Efficient seawater to drinking water machine.

- Versatility: Additionally, we offer the possibility to make every water maker we distribute into a simple water desalination system.

- Clean Drinkable Water: Ensure your boat, yacht, or cruiser always has clean water aboard. Take advantage of all the salt water around you while cruising. Turn it into drinkable water with our desalination devices. The best part is your own engine will power all water production.

Engine Driven Water Makers Models

| Model | Fresh Water Prod. GPH/GPD | Boost Pump Amps 12VDC | Price |

|---|---|---|---|

| SM25E | 25/600 | 5 | $4700 |

| SM45E | 45/1080 | 5 | $5850 |

| SM55E | 55/1080 | 5 | $6750 |

* Any Engine-Driven Water Maker can be made into a Simple Water Maker. The simple models SM25ES, SM45ES and SM55ES, do not include the standard remote control panel and mount the system controls on the end of the RO Pressure Vessel. These engine-powered desalination systems are $395 less than engine-driven versions.

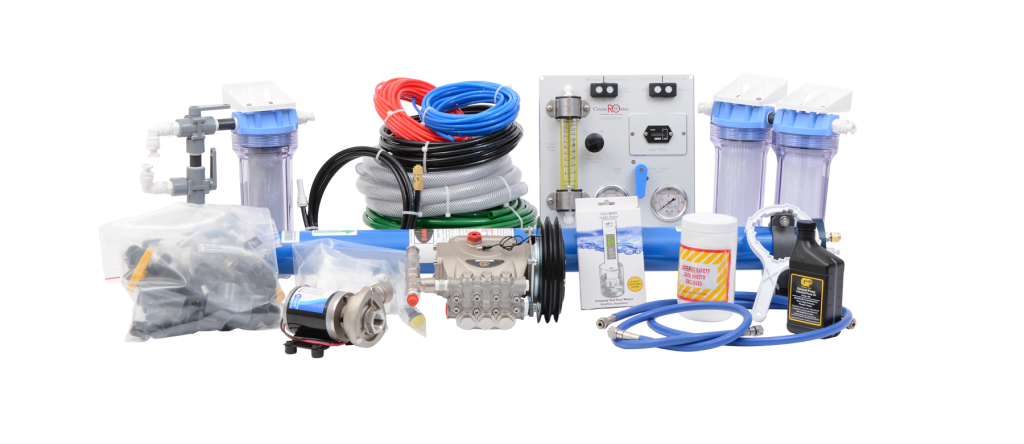

Parts Included in Our Engine Driven Water Makers

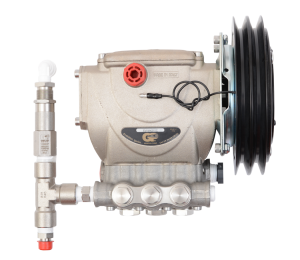

High Pressure Pump and Clutch Assembly

One General Pump Company triplex plunger pump with a 316 stainless steel manifold and wetted parts. It also includes solid ceramic plungers and a nickel-plated crankcase mechanically coupled to a dual v-belt electrically engaged clutch. Fitted with a pressure relief valve preset to 950 PSI.

One General Pump Company triplex plunger pump with a 316 stainless steel manifold and wetted parts. It also includes solid ceramic plungers and a nickel-plated crankcase mechanically coupled to a dual v-belt electrically engaged clutch. Fitted with a pressure relief valve preset to 950 PSI.

(SM25E): RO Pressure Vessel Assembly

One filament wound fiberglass/epoxy pressure vessel

OneDow Filmtec Polyamide thin-film composite high salt rejection RO Membrane

Two Stainless Steel clamps affixed to fiberglass mounting feet.

(SM45E): RO Pressure Vessel Assembly

Two filament wound fiberglass/epoxy pressure vessel

Two filament wound fiberglass/epoxy pressure vessel

Two Dow Filmtec Polyamide thin-film composite high salt rejection RO Membrane

Four Stainless Steel clamps affixed to fiberglass mounting feet.

(SM55E): RO Pressure Vessel Assembly

Three filament wound fiberglass/epoxy pressure vessel

Three filament wound fiberglass/epoxy pressure vessel

Three Dow Filmtec Polyamide thin-film composite high salt rejection RO Membrane

Six Stainless Steel clamps affixed to fiberglass mounting feet.

Pre-filter and Boost Pump Assembly

Two 10” clear filter housings with mounting bracket

One 20 micron pre-filter element

One 5 micron pre-filter element

One12V DC Jabsco centrifugal boost pump

Valving and Cleaning Assembly

One clear filter housing with mounting bracket

One activated carbon filter element

Two 3-way valves for selecting: normal operation of fresh water rinse from ships tanks or pickling solution.

Remote Control Panel

An anodized aluminum panel with the following system controls:

One 0-1 GPM flow meter

One 0-1500 pressure gauge

One stainless steel product water selector 3-way valve

One stainless steel pressure regulating needle valve

One 12VDC boost pump electrical switch

One 12VDC High Pressure clutch switch

One 0-60 boost pump pressure gage

SM25E – 0-1 GPM flow meter

SM45E – 0-1 GPM flow meter

SM55E – 0.2- 2.0 GPM flow meter

Optional Remote-Control Panel with TDS Meter (+$200)

Replaces standard hour meter with on-panel real-time TDS meter display ($200 adder)

Replaces standard hour meter with on-panel real-time TDS meter display ($200 adder)

Miscellaneous Included Equipment & Supplies

30ft of green 1/2″ Polyethylene sea water tubing

30ft of green 1/2″ Polyethylene sea water tubing

30ft of blue 1/4″ Polyethylene product water tubing

30ft of Black 3/8” Polyethylene brine water tubing

40ft of red 1/4″ Polyethylene brine water tubing

25ft of clear braided polyvinyl tubing

One cutter for the water tubing

One 1/2″ male NPT to push connector fitting for connecting to your seawater inlet source

One 1/2″ male NPT to push connector fitting for connecting to your ships water system for fresh water flushing of the water desalination system

Three 1/4″ male NPT to push connector fittings for connecting the brine, product water, and sample water outlet lines to your ships plumbing

Locking clips for all push connector fittings

Electronic copy of the Installation, Operation and Maintenance manual

One filter housing wrench for filter element replacement

2.5 pounds of pickling reagent

One hand-held TDS meter for checking water quality (Not included when purchasing the control panel with TDS digital Display

Two spare 1/2” 90 degree push-to-connect elbow fittings, if needed, to replace the straight fittings which are pre-mounted on the modules for making the system plumbing easier

A second bag of assorted 3/4” tees, fittings, and clamps is provided for the installation of the ¾” components

High Pressure Hoses

One 3ft long 3/8″ high pressure braided stainless steel silicone covered hose for connecting the high-pressure pump outlet to the RO pressure vessel.

One 5ft 3/8″ high pressure braided stainless steel silicone-coated hose

Longer or shorter high-pressure hoses available for an additional $10 per foot.

Dimension for the Parts of Our Engine Driven Water Makers

The below table provides the length, width, height, and weight of the various water desalination system modules:

- The listed dimensions represent the greatest size measurement to create a box within which the module can be contained.

- However, as seen in the module photo images, it could fit into a smaller space. It will depend upon the installation orientation.

- These dimensions do not include the room needed for wires or hoses to enter or exit the equipment.

- All equipment comes with straight fittings.

- Optional 90-degree fittings are available.

| Module | Length (inches) | Width (inches) | Height (inches) | Weight (pounds) |

|---|---|---|---|---|

| Pump and Clutch | 10.5 | 9.5 | 7.5 | 24 |

| (SM25): RO Pressure Vessel | 45 | 5 | 6 | 15 |

| (SM45): RO Pressure Vessel | 45 | 10 | 6 | 30.5 |

| (SM55): RO Pressure Vessel | 45 | 15 | 6 | 46.5 |

| Prefilter Assembly | 13.75 | 9.75 | 5 | 5.2 |

| 12V DC Boost Pump | 6.5 | 4.5 | 4.25 | 5.3 |

| Valving and Cleaning Assembly | 13.5 | 5 | 14.5 | 5 |

| Remote Control Panel (Standard Hour Meter) Depth protruding from back of panel | 2.875 Depth | 11 | 11.25 | 4.5 |

| Remote Control Panel (Optional TDS Meter) Depth protruding from back of panel | 3.5 Depth | 11 | 11.25 | 4.75 |

| Optional: Automatic Fresh Water Flush ($649) | 9.75 | 8 | 4 | 3 |

*Please notify us if you plan a 24VDC installation so we can change the standard 12VDC electrical switch for your boost pump in your remote panel.

* Standard Boost pump is a 12VDC self-priming pump.

(Here is a link to a Video we made explaining why we like the 12V DC pump)

* A 120VAC Boost pump option available using 1.5Amp + $200

* A 24VDC Boost pump is available using 6.5Amp + $200

Parts NOT Included in Our 20-60 GPH Water Makers

Watch the video to the right going over the details:

- Raw water through hull and shutoff valve.

- Raw water sea strainer (we recommend one like this).

- Electrical installation wire and breakers for the AC and DC Pumps.

- Mounting screws and bolts for the individual system modules.

- Zip ties and mounting straps for securing the electrical and water lines.

That’s it! Everything else we provide with the with the water maker.

To request a copy of the SeaMaker water maker manual with technical specifications along with detailed installation and operation instructions, click the button below.

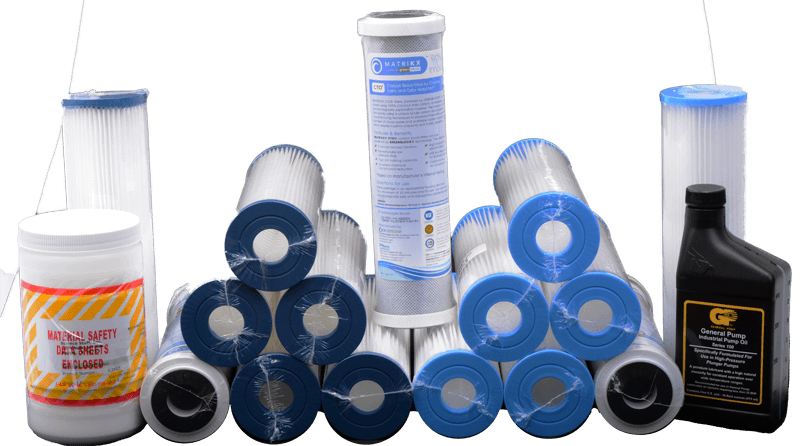

Cruising Consumable Kit

We put together the Cruising Consumable Kit with everything you will need. Cut the dock lines and head out cruising for a year or more for

$165

- 20 and 5 micron pre-filters

- Pickling reagent

- Activated carbon filters

- High pressure pump crankcase oil

*** The SeaMaker Simple line (SM30S, SM30S) does not come with a remote panel. The Simple water makers simply mount the needed system controls on the RO Pressure Vessel.

To request a copy of the SeaMaker water maker manual with technical specifications

along with detailed installation and operation instructions, click the button below.

Why Choose Cruise RO Water and Power?

Experience

Experienced cruisers and industrial manufacturers craft our commercial watermakers. Our firsthand knowledge ensures the finest onboard solutions for your water production needs.

Quality

At Cruise RO Water and Power, we are committed to excellence. Offering only products we believe in, our quality assurance ensures reliability and peace of mind for every voyage.

Affordability

Discover affordability without compromise at Cruise RO Water and Power. Our watermakers, crafted with no proprietary parts, deliver high quality at a price that won’t break the bank.

Adaptability

Experience the power of customization with Cruise RO Water and Power. Our adaptable solutions mean watermakers crafted uniquely for your boat, cruiser, yacht, or any boat you own.

FAQs About Boat Water Makers

How Does Reverse Osmosis Work?

Reverse osmosis is a water treatment process that filters out impurities and contaminants from seawater, making it safe for consumption. Here’s a simplified breakdown of the process:

- Prefiltration: Removes larger impurities to protect the semipermeable membrane.

- High-Pressure Pump: Forces finely filtered seawater through the membrane at up to 1000 psi pressure.

- Semipermeable Membrane: Allows only water molecules to pass, leaving concentrated brine.

- Post-Filtration: Eliminates remaining contaminants for top water quality.

- Storage and Distribution: Freshwater is stored and distributed throughout the vessel.

Reverse osmosis technology ensures access to safe and clean drinking water during marine journeys.

What Does a Reverse Osmosis System for Boats Do?

By definition, a water maker is a device used to obtain drinking water from seawater. The process to remove salt from water is called reverse osmosis. Water makers remove salt and other contaminants from seawater and brackish water. As a result, they produce a continuous desalinated seawater supply that is safe to drink.

Not only do reverse osmosis systems solve the dilemma of making saltwater freshwater, but they are very convenient. These devices can be quite valuable to have on board because they reduce the need for large water tanks for a long passage.

How Long Does it Take to Make Fresh Water?

Reverse osmosis is a process used to remove dissolved minerals and impurities from water from a salinated water source. It uses pressure to force water molecules through a semipermeable membrane. Desalination plants often use this process to remove salt and impurities from seawater, turning it into fresh drinking water.

The time it takes to purify salt water to drink depends on the water maker. Some water makers can create fresh water in a few hours, while others may take more time.

The size, capacity, and other features added to the water maker also affect production time.

Is Reverse Osmosis Water Good For You?

RO water isn’t merely safe—it’s beneficial in several ways:

- Filtered Contaminants: Reverse osmosis is one of the most comprehensive water filtration methods. It removes lead, asbestos, and 82 other pollutants, including bacteria, viruses, nitrates, sulfates, fluoride, and arsenic. The small membranes in RO filters can even remove dissolved chemicals and minerals from the water, reducing it to its most basic molecules.

- Better for the Environment and Safer than Bottled Water: RO is a safer and more environmentally friendly alternative if you frequently rely on disposable plastic water bottles. It could save you hundreds or even thousands of dollars annually.

Can You Drink Reverse Osmosis Water Everyday?

Reverse osmosis water, or RO water, is purified drinking water that has become increasingly popular due to its perceived health benefits.

Reverse osmosis (RO) is a water purification process that eliminates many contaminants, including bacteria, viruses, heavy metals, and chemicals. This makes RO water safe for human consumption, especially for those concerned about the health risks impurities pose in regular tap water. However, it is important to note that RO removes healthy minerals like calcium, magnesium, and potassium, which can affect water’s taste and health benefits.

Does Reverse Osmosis Waste Water?

Yes, RO does generate wastewater, and the amount depends on factors such as water pressure and the condition of the RO filter. A system operating below 35-40 PSI or with a worn-out valve tends to be less efficient, resulting in increased water wastage.

However, recent advancements in membrane technology have produced more efficient RO systems, with some achieving a 1:1 ratio of permeate to concentrate production. This signifies that only one gallon of reject water is produced for each gallon of treated water.

Questions? We Are Here To Help.

Email or call and talk to the owners of the Company and the Designers, Rich and Charlie, 7 Days-A-Week. If they are awake, they answer!

SALES & TECH SUPPORT

MANUFACTURING & SHIPPING

SKYPE