Reverse Osmosis Systems are more than just essential equipment for solo sailors and businesses that provide yacht or boat services; they are also investments.

RO Systems require maintenance to continue performing optimally, protect such an important investment, avoid unplanned downtime and unexpected repair costs, and reduce the risk of contamination.

This post will cover why reverse osmosis systems need maintenance, the importance of well-performed maintenance, and five tips from Cruise RO Water and Power for optimal Watermaker maintenance.

Importance of RO Systems Maintenance

A reverse osmosis system is a type of water filtration system that uses pressurized water to force molecules through a semi-permeable membrane to remove impurities from the water and convert it into clean water. This process is called “reverse osmosis” because it is essentially the opposite of natural osmosis, which occurs when molecules move from an area of high concentration to a place of low concentration.

Maintenance on reverses osmosis systems demands a series of procedures because they are constantly exposed to saltwater and other elements that can cause corrosion and damage to their parts.

Some of the most essential maintenance practices include:

- Replacement of old parts with new ones

- Inspection of the system’s components

- Cleaning the filters

- Checking for leaks

- Testing the system’s performance levels by running it through several cycles.

5 Tips on Maintaining a Reverse Osmosis (RO) Watermaker

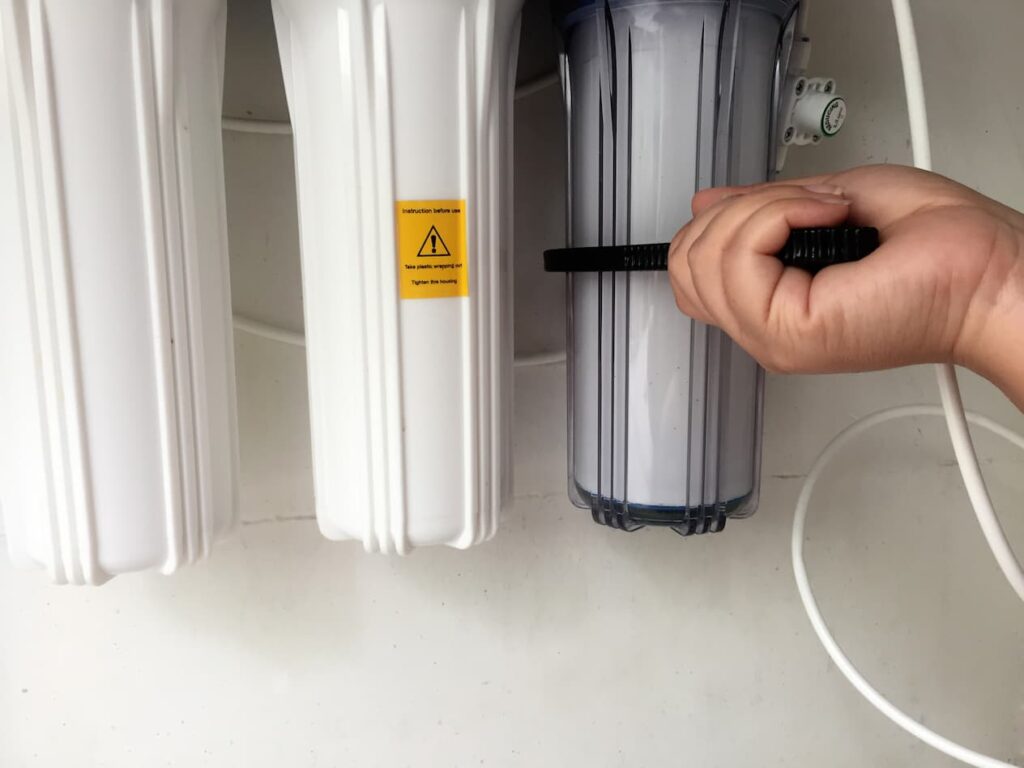

1. Change the Filters Once a Year

First and foremost, make sure that all filter cartridges are changed out at least once every year (preferably twice per year if possible), depending on how much use your RO system gets throughout the season. This ensures that any sediment or other contaminants won’t build up over time and clog or damage your unit’s internal filters or membranes.

But remember: Even if the system is not used regularly, it still requires yearly maintenance to ensure that all its components are working properly.

2. Clean and Replace the Membranes Regularly

Reverse osmosis membranes should be inspected regularly for signs of damage or wear, such as cracks or discoloration. If damaged, membranes should be cleaned or replaced immediately to avoid further damage or contamination issues.

3. Check the Pressure Gauges

Pressure gauges should indicate steady flow throughout the treatment cycle; if they don’t, there may be an issue with the membrane or other components needing attention.

4. Regularly Flush Membranes

Flushing out your membranes every few months helps keep them clean and efficient by removing any built-up residue or contaminants that could cause clogs or blockages in your system over time.

5. Always Store Fresh Water

When not used for extended periods, ensure you fill your tank with fresh water to remain clean and odor-free until you need it again.

An extra piece of advice: Have an experienced technician examine & flush out your entire unit annually to remove any calcium buildup from hard water sources like dockside connections which can damage internal membranes over time if left unchecked.

By properly maintaining your reverse osmosis watermaker, you can rest assured that you will have clean drinking water available whenever you need it, no matter where you go!

The Best Equipment for Expert Maintenance

To ensure that your reverse osmosis system is properly maintained, it’s important to have the right equipment. Cruise RO Water and Power offers a full line of quality maintenance products to keep your watermaker in top condition. Their selection includes everything from filter cartridges and membranes to pressure gauges and flush kits, which are essential for expert maintenance. With quality parts and professional service, you can trust Cruise RO Water and Power to help keep your watermaker running smoothly for years to come. Call us or fill out our contact form to get in touch today!