Frigomar Boat Refrigeration

As a certified distributor of Frigomar USA, we offer top-quality marine refrigeration systems manufactured in Italy. Frigomar USA designs these units to meet and exceed industry standards. They each provide the reliability and durability you seek for your marine refrigeration needs. Explore our products to find efficient and advanced refrigeration for your sailboat, cruiser, yacht, or any vessel.

Checkout Our Satifies Customers Testimonials

Centralized Refrigerators

These centralized cooling refrigerators redefine convenience and luxury on board. They include five exceptional products, including custom systems, wine coolers, and compressors. Experience superior cooling performance tailored to your specific needs. Elevate your boating adventures with Frigomar USA’s centralized refrigeration for sailboats, yachts, cruisers, and all kinds of vessels.

Custom-Made

Refrigerators

Centralized marine refrigerators and freezers designed and manufactured to meet the needs of our clients.

- Volumes up to over 50/100 m3

- Stainless steel (AISI 316) construction

- Shape and dimension are completely customizable

- Variety of exterior layouts

- “Customizable” stainless steel interior layout

- Includes flush doors, or hinged door designs

- Custom refrigerators, freezers, refrigerators and freezers combined, wine cellars, walk-in, and more.

Standard Centralised Refrigerators

Standard centralized fridges for small boats and other specific uses.

Models:

3071 – 40 lt.

3073 – 75 lt.

3075 – 130 lt.

- Interior made of white ABS

- Thermostatic expansion valve R134a

- Door with satin stainless steel (AISI 316) panel

- Magnetic closure with locking mechanism

- Vertical evaporator (standard)

- Box evaporator (optional)

Cold

Rooms

Cold Rooms and walk-in pantries are custom-designed and built to client specifications.

- Cold room volume 11 m3

- Freezer room volume 8 m3

- Room temperatures +1°C / -20°C

- 2 hermetic compressors

- 4 evaporators with programmed defrosting for no-frost management

- Power supply 400-440V/3/50-60Hz

Wine Coolers

Tailor-made wine coolers

- Shelves made of stainless steel or wood

- Removable shelves

- Flush or hinged doors

- Self-locking handle

- Customized finish

Compressors

- Open Compressors

Models:

511 – up to 1240 BTU

511S – up to 2000 BTU

- Combined AC/DC Compressors

Models:

505 – up to 1240 BTU

505S – up to 2000 BTU

- Hermetic Compressors

Models:

38, 41, 549, 550, 551, 552, 553, 554, 555 – R134a/R404a

39 – 40 R134a

Frigomar USA’s Self-Contained Refrigerators for Sailboats and Boats

From tailored solutions to standalone units, Frigomar USA’s self-contained refrigerators for sailboats and boats deliver exceptional performance. These systems keep your provisions fresh and make your boating experiences unforgettable. Choose a self-contained refrigerator for your boat from custom and standard independent options.

Custom-Made

Refrigerators

Independent marine refrigerators and freezers are designed and manufactured to meet the needs of our clients.

- Volumes up to over 50/100 m3

- Stainless steel (AISI 316) construction

- Shape and dimension are completely customizable

- Variety of exterior layouts

- “Customizable” stainless steel interior layout

Includes flush doors or hinged door designs

Standard Independent Refrigerators

Standard independent refrigerators for small boats and other specific uses.

Models:

Serie 60 – 12/24 Volt C.C.

Serie 70 – 12/24 Volt C.C.

Serie 90 – 12/24 Volt C.C.

Serie 120 – 230 Volt A.C.

- Interior made of white ABS

- Stainless steel interior on the 90 series

- Door with satin stainless steel (AISI 316) panel

- Magnetic closure with locking mechanism

- Refrigeration units can be incorporated or separated.

- Flat evaporator (standard)

- Box evaporator (optional)

Frigomar USA’s Extensive Selection of Accessories for Marine Refrigeration System

Enhance your marine refrigeration system with Frigomar USA’s extensive selection of accessories. From electric switchboards to replacement parts, we offer everything you need to optimize and maintain your system’s performance. Explore our comprehensive range of high-quality accessories, ensuring seamless operation and peace of mind on the water.

Electric Switchboards

- Standard Electric Switchboards

For the complete management and control of the Refrigeration system.

Models:

1230, 1231 – 2 solenoids

1232, 1233 – 3 solenoids

1234

- Custom-Made Electric Switchboards

Made-to-measure switchboard to completely control and manage complex, comprehensive refrigeration systems.

Refrigeration Components

Refrigeration component selection includes:

- Outboard condensers

- Counterflow condensers

- Structural tank condensers

- Custom-made eutectic plates

- Roll-bond flat plate evaporators

- Roll-bond box plate evaporators

- Fan evaporators

- Thermostats

- Refrigerant gas tanks

- Pumps 12/24 V DC

Replacement Parts

Replacement parts include:

- Expansion valve

- Filter

- Solenoid valve

- Liquid indicator

- Piston pin and connecting rod

- Gas tank with sight glass and taps

- Bitzer type “0” compressor with flywheel

- Silent block

- Brushes

- Bearing

FAQs

Boat AC units work with a series of components that together provide cool and comfortable air on board:

- The compressor serves as the engine, pressurizing the refrigerant gas to raise its temperature significantly.

- The condenser then releases heat, turning the gas into a high-pressure liquid.

- The expansion valve controls the flow of the liquid, reducing its pressure and temperature.

- In the evaporator, the refrigerant absorbs heat from the surrounding air, creating cold air for the cabin.

- A blower fan ensures proper air circulation, while a return air grille and filter clean and enhance air quality.

Follow these steps to winterize your boat AC unit:

- Remove any debris, dust, or dirt from the unit.

- Disconnect the AC unit from any power sources.

- Drain any water from the air conditioner and its water lines.

- Check the refrigerant levels. If they are low, recharge the unit to the manufacturer’s recommended levels.

- Contact a qualified marine mechanic in order to recharge the AC unit.

- Inspect the AC unit’s wiring and insulation for signs of wear, damage, or rodent infestation

- Finally, cover the air conditioner with a sturdy, weatherproof covering.

Here are some tips for troubleshooting your boat’s AC system:

- Clean the vents and filters.

- Check the AC pump for any leaks or odd noises.

- Check the blower for any damage or blockages and the ducts for leaks or disconnections.

- Look for any fault or warning messages on the display panel.

- Check the AC system is powered and that all connections are safe.

- Check for a clogged drain and remove any blockages.

- Check refrigerant levels and contact a professional if you suspect a leak.

- Look for ice accumulation or debris in the evaporator coil, and clean it if necessary.

- To install your marine refrigeration system, you need to gather the tools and materials. These include the marine AC system, wiring, a circuit breaker, mounting brackets, and insulation materials.

- Select a suitable location for the AC unit. Prioritize ventilation and easy maintenance access.

- Securely attach the AC unit to the chosen location using the mounting brackets.

- Carefully install the ducting to ensure optimal airflow throughout the boat’s interior.

- Follow the manufacturer’s guidelines to connect the AC unit to the boat’s electrical system.

The cost of an AC unit can vary widely. Brand-new, basic units for smaller boats can be as low as $1,200, while larger, more advanced units with enhanced features may cost $2,000 or more. Installation costs, typically ranging from $3,000 to $4,000, should also be considered for a complete estimate. Professional installation is vital for ensuring long-term efficiency.

To determine the appropriate size of your boat AC unit, follow these steps:

- Determine the total cubic footage of the area you intend to cool.

- Evaluate the insulation and sun exposure of the area, as well-insulated spaces will require less cooling capacity.

- Account for heat-producing equipment like ovens or machinery and add their heat load to the cooling requirement.

- Consider the number of occupants projected for the boat and select an air conditioner with higher capacity for frequently occupied spaces.

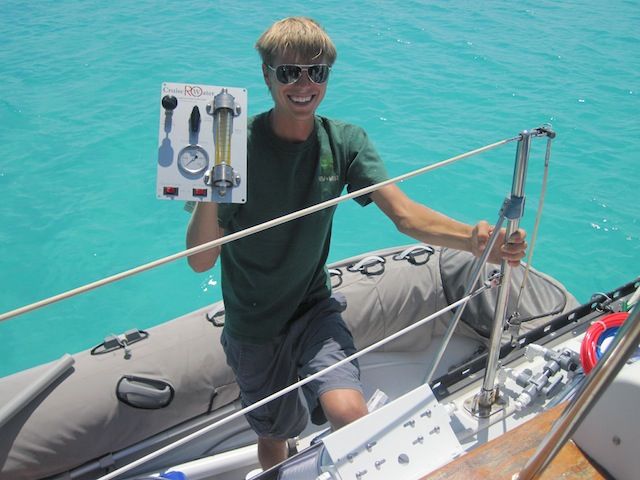

Why Choose CruiseRO Water and Power?

Experience

At CruiseRO, we are experienced sailors ourselves. We offer only trusted sailboat refrigeration units, ensuring our clients set sail with confidence.

Quality

Discover excellence with Frigomar USA products at CruiseRO. Reap the benefits of the finest Italian craftsmanship and cutting-edge technology.

Affordability

Sail smart with cost-effective marine refrigeration units. Enjoy quality and savings as you keep things, from food to water, cool on your journey.

Adaptability

Explore our extensive range of Frigomar USA equipment. We ensure you’ll find the perfect fit for your size, capacity, and quality requirements.

What Cruisers Have to Say about CruiseRO’s Water Markers

Questions? We Are Here To Help.

Email or call and talk to the owners of the Company and the Designers, Rich and Charlie, 7 Days-A-Week. If they are awake, they answer!

SALES & TECH SUPPORT

MANUFACTURING & SHIPPING

SKYPE